Great Northern – Fiber Interior Packaging Frequently Asked Questions

Below you will find some of the most common questions about our protective packaging solutions. If you are unable to find an answer to your question in the information below, please contact one of our fiber interior packaging specialists!

- Easy to pack

- Biodegradable

- Easily recyclable

- 100% recyclable curbside, same as any paper-based product

- Nest-able

- Requiring less warehouse space

- Customization

- Tailored to your specific product, providing optimum product protection

- Transit Testing

- Great Northern has an ISTA® 6 Certified Laboratory

- Able to conduct

- ISTA 1A, 3A, FedEx 6A and Amazon SIOC 6A (Ship In Own Container)

- Tests may include: vibration, inclines, material handling, free-fall drops and compression tests

- 100% Recycled – Made from used corrugate and newsprint

- Biodegradable – The US Environmental Protection Agency defines Biodegradable as any substance that has the ability to be broken down physically and/or chemically by microorganisms

- Our parts are produced by creating a slurry made from mixing used corrugated and newsprint with water. The slurry is then pulled through a tool that molds the part, then dried

- Product needs protection from damage in shipping

- Current packaging process is labor intensive

- Packaging needs to be more sustainable / environmentally friendly

- Product weight is 100 lbs. or less

- Many E-Commerce items

- Containers

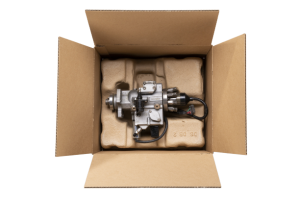

- Automotive parts and accessories

- Exercise equipment

- Outdoor equipment

- Small engines

- Power tools

- Industrial B2B products

- Paint Cans

- Lights

- Cooking oils

- Batteries

- Compressors

- HVAC equipment

- Health supplements

- and more!

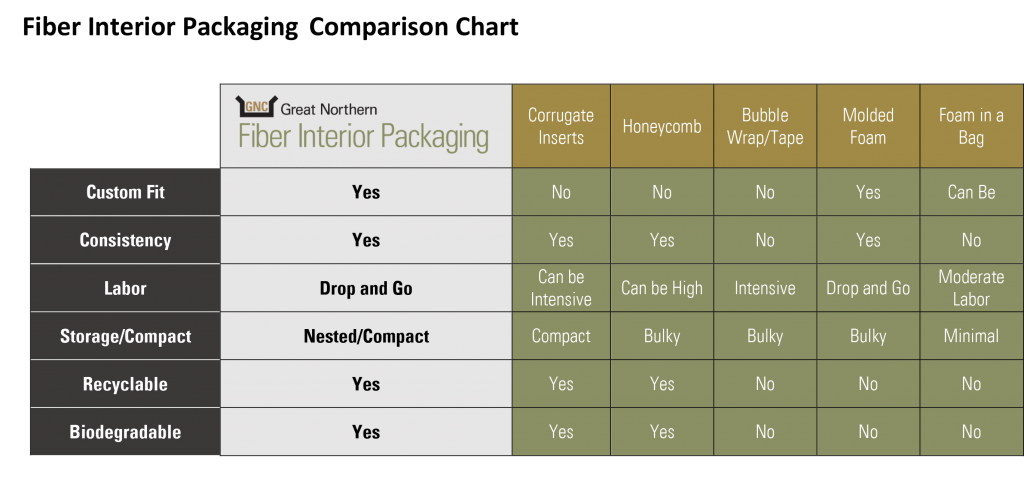

Foams including expanded polystyrene, aka EPS or Styrofoam®, foam in a bag and foam in place

- Cannot be easily recycled

- Are not seen as environmentally responsible

- Require more space because the parts do not nest

- Corrugated die-cuts

- Highly labor-intensive

- Not molded to fit contours of the item

- Can require multiple parts

- Honeycomb

- Parts do not nest and require more space

- Not molded to fit contours of the item

- Bubble Wrap

- Resistant to biodegradation

- Items must be individually wrapped and taped for shipping which is very time-consuming and labor-intensive

A price estimate can be provided in just a few days once we receive your product and/or a drawing with dimensions and annual volumes

Assuming the above preliminary pricing meets your requirements, we will require a sample of the part to design the tooling and provide a formal quote.

- Samples

- Once you have approved the design and pricing, we will require a Purchase Order for the production of samples to begin

- Production

- Production can be initiated once we receive approval of samples and a Purchase Order for production of parts to begin

Since they’re produced from 100% paper products, parts can easily be re-entered into any paper or corrugated waste stream.

Ensure product & package protection with our ISTA 6 testing and certification services.

Great Northern’s ISTA 6 Test Lab exposes packages to conditions and hazards including:

- Vibration

- Inclines

- Material Handling

- Free-fall Drops

- Compression

Testing your packaging solution before sending it to your end-user ensures that your product will arrive damage free every time! Click here to learn more about our testing facility.

Foams including expanded polystyrene, aka EPS or Styrofoam®, foam in a bag and foam in place

Foams including expanded polystyrene, aka EPS or Styrofoam®, foam in a bag and foam in place