Professionals operating in the direct-to-consumer world know the value of custom packaging solutions. You want your original goods to reach customers in the same condition you shipped them. One method for streamlining your efforts is to use molded fiber, which can accommodate items of different shapes and sizes.

Table of Contents

- Taking Charge in the Sustainable Packaging Revolution

- A Custom Fit for Every Product You Create

- Versatile Molded Fiber Applications for Your Industry

- Customizations to Impress Your Customer

- The Right Packaging Partner for Consumer Goods

- Contact Us for Packaging Details

Taking Charge in the Sustainable Packaging Revolution

Lightweight fiber packaging is taking the direct-to-consumer shipping process by storm. Fortune Business Insights reports that the world’s molded fiber packaging industry was valued at just over $8 billion as of 2023, and we could see this valuation increase to more than $12.5 billion by 2030.

The same study indicates that North America sits at the top of the sustainable packaging revolution, with over 39% ownership of the market share. Fiber packaging solutions are growing increasingly popular in the delivery of e-commerce goods due to their durability and ability to take on custom shapes that accommodate exact specifications.

Unlike plastic, foam and airbag alternatives, sustainable molded fiber materials are 100% recyclable. Professionals and customers appreciate that molded fiber solutions break down quickly and are fully compostable. Incorporating these materials into workflows enables businesses to shrink their carbon footprints and makes customers feel good about their decision to work with companies that are taking environmentally responsible initiatives.

A Custom Fit for Every Product You Create

Molded fiber packaging consists of cellulose fibers. These fibers are extracted from things like plants, cardboard and recycled parchment. Some varieties are sourced from wood and bamboo.

Sustainable molded fiber materials are made by melting cellulose fibers into a slurry. The solution can be used to fill custom molded fiber shapes in which the slurry hardens to meet the dimensions of the inserts. When original products are encased inside the finished packaging, items are appropriately cushioned and ready for shipping.

Molded fiber packaging is far from new, but direct-to-consumer businesses are catching on to its ease of use. You have endless options for getting products to their destination safely and quickly. Package units yourself with reduced assembly demands compared to more traditional packaging solutions.

Versatile Molded Fiber Applications for Your Industry

Companies are transitioning to molded fiber packaging to ship the most delicate cargo. It’s common for businesses in the food and beverage, electronics, utilities, cosmetics and household goods industries to use molded fiber solutions for their practical design elements, protection and visual aesthetics:

- Glass jars: Use custom-fit packaging to help airtight jars reach customers free of cracks, chips and spills.

- Kitchen appliances: Customers can feel confident that their new microwave, coffee maker or fridge will arrive safely.

- Liquors: Send cocktail mixtures and bottled liquors to customer doors, knowing that surfaces get sufficient cushioning.

- Beauty items: Transport mascaras, moisturizers, shampoos, and creams with peace of mind.

- Vitamins and supplements: Safeguard health products with packaging that has the same dimensions as the bottles to save space.

- Paint cans: Shipping paint primers and color coats with molded fiber materials can minimize unwanted vibration.

- Sports and fitness gear: Be confident in your ability to distribute parts for exercise machines, weights and clamps.

- Lighting: From overhead lighting fixtures to light bulbs, fiber packaging gets the job done easily.

- Power tools: Use resilient molded fiber inserts to surround and protect drills, electric saws and power washers.

- Batteries: Make sure the batteries you send to customers arrive without unwanted punctures and dents.

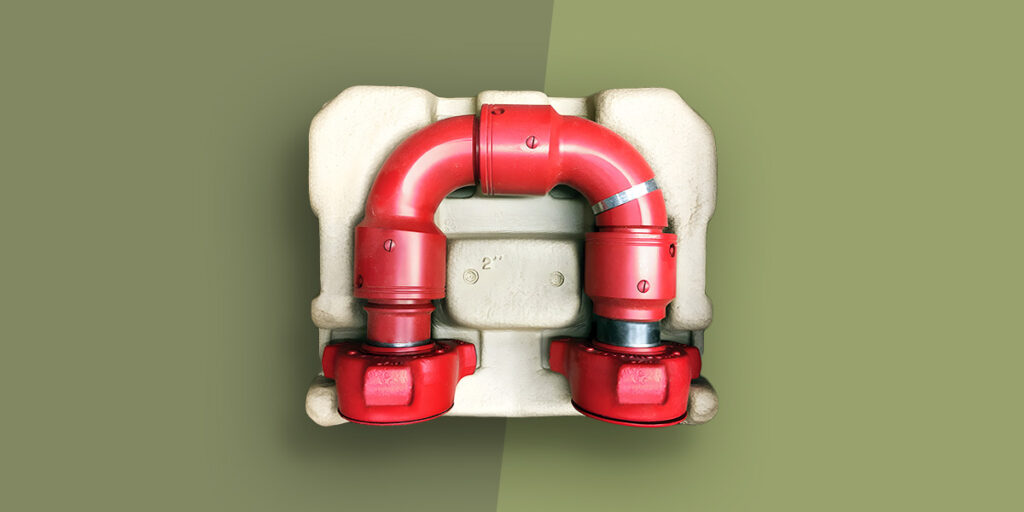

- HVAC technology: Ship delicate ductwork connections, fuses, PVC or metal housings to a project site.

This is just scratching the surface of how businesses can use molded fiber solutions to move fragile or irregular-shaped items.

Customizations to Impress Your Customer

Molded fiber packaging does more than act as a means to protect and secure items during transit. Decision makers enjoy numerous customization options to take the customer experience to the next level.

Creating a package that is unique to your brand goes a long way in helping your customer base identify your products and recognize your attention to detail. Depending on your industry, you might select molded fiber packaging that leaves specific compartments for bundled items, such as charging cables, additional hardware, accessories and instruction manuals. Keep all materials related to a shipment in one place for a special unboxing experience.

The Right Packaging Partner for Consumer Goods

Great Northern Fiber Interior Packaging creates molded fiber solutions tailored to your individual projects. We partner with companies throughout the U.S. and specialize in cross-country shipping operations for your convenience. All of our products are totally recyclable, and we’re known for our ability to complete ISTA 6 Testing from our facility in Appleton, Wisconsin. Our experts are proud to work with anyone in need of protective packaging to ship directly to consumers.

Contact Us for Packaging Details

At Fiber Interior Packaging, we significantly reduce labor costs without compromising the safety and security of e-commerce products. We’re also a member of Amazon’s Packaging Support and Supplier Network (APASS), which means we have experience designing and creating molded fiber inserts for a long list of products.

Contact us today to learn more about our capabilities and process.