Molded fiber is a durable, sustainable and protective packaging option, perfect for shipping various products. This eco-friendly solution is recyclable and customizable, helping you improve your company’s sustainability efforts while securing your unique products for shipment. Different types of molded fiber offer unique benefits, so it’s important to understand how each type can impact your shipping.

Types of Molded Fiber Protective Packaging

Understanding molded fiber pros and cons is essential when choosing the right option for your products. Each of the following molded pulp types offers different advantages:

Type 1: Thick Wall

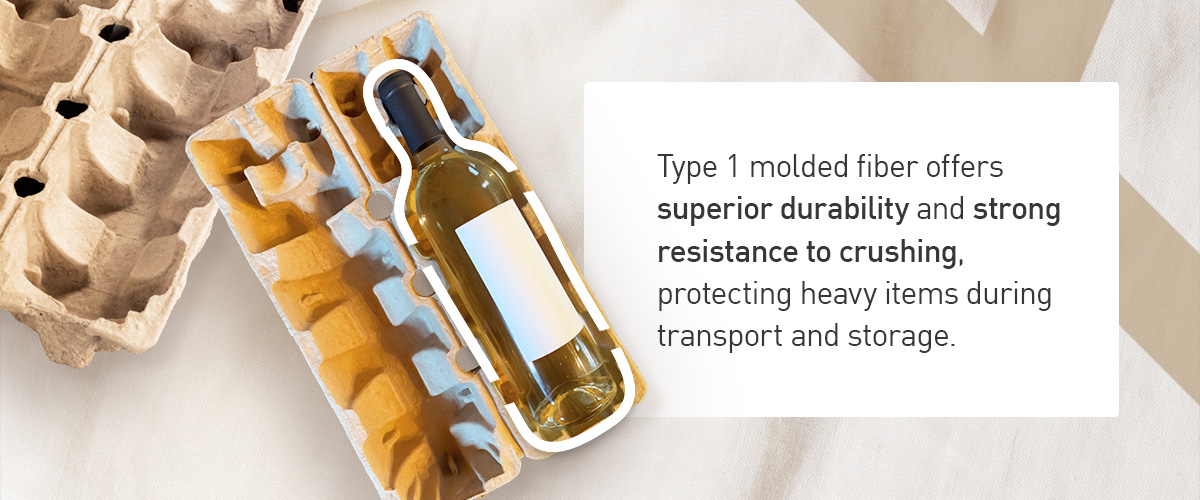

Type 1 molded fiber is oven-dried and offers a wall thickness between 3/16 and 3/8 inches. It features a smooth inner surface and a rough outer surface for excellent grip and stacking stability. This substantial structural integrity makes it the heaviest-duty option in the molded fiber family.

While it’s not ideal for lightweight products, thick-wall molded fiber packaging excels at protecting heavier, non-fragile products such as the following:

- Appliances

- Vehicle parts

- Pumps

- Glass jars and bottles

- Furniture

Type 1 molded fiber offers superior durability and strong resistance to crushing, protecting heavy items during transport and storage. It’s also a cost-effective option for bulk applications. Type 1 molded fiber’s thickness makes it bulkier and heavier than other options.

Type 2: Transfer Molded

Type 2 or transfer-molded fiber packaging consists of dual-mold construction. It combines one forming mold and one transfer mold to create a wall thickness between 1/8 and 3/16 inches. Similar to Type 1 molded fiber, it features one smooth and one rough side, unless it undergoes further processing. It’s common for egg cartons and trays but can also protect the following products:

- Electronics

- Candles

- Lightweight consumer products

Transfer-molded fiber packaging’s manufacturing method allows for more precise detail and control than thick-wall molded fiber. It’s a versatile option for products requiring moderate protection with a greater aesthetic appeal. You can rely on it for functional and decorative applications. Transfer-molded fiber is less protective than thick-wall molded fiber, but it’s the ideal option if you need to ship lighter-weight items.

Type 3: Thermoformed or Thin Wall

Thermoformed or thin-wall molded fiber is the most refined and aesthetically appealing protective packaging option. It’s manufactured with multiple-headed molds, drying products directly into the mold and eliminating the need for separate oven curing. It offers smooth surfaces with minimal draft angles and a thinner wall thickness ranging between 3/32 to 5/32 inches.

Type 3 molded fiber’s finished appearance closely resembles thermoformed plastic. It’s a great choice for lightweight, fragile items requiring an upscale presentation. This type of molded fiber is common for products such as:

- Cosmetics

- Gourmet food products

- Electronics

- Specialty retail items for which appearance is just as important as protection

Thin-wall molded fiber is less protective than Types 1 and 2, and it has a higher manufacturing price per unit. It’s limited to lightweight products, and its smooth surface can present stacking challenges.

Type 4: Processed

Type 4 or processed molded fiber can be Type 1, 2 or 3 molded fiber that undergoes secondary treatment after initial molding and curing. Secondary treatments may involve:

- Perforation

- Die-cutting

- Hot pressing

- Coloring

- Printing

- Adding custom design features

Processed molded fiber’s unique customization layer helps packaging meet specific aesthetic, brand or functional requirements. It has a significantly higher cost and longer lead times than Types 1, 2 and 3 molded fiber due to the secondary processing, but some companies use this type to differentiate their packaging. Special features may include custom brand messaging, hinged designs or ventilation holes.

What Type of Molded Pulp Is Best for Shipping?

Determining which molded fiber type is best depends on the types of products you ship. Types 1 and 2 are the most protective options. Choose Type 1 for maximum protection for heavy items, or Type 2 for lighter-weight items or more decorative packaging options. Types 1 and 2 are the most durable types of molded fiber packaging, offering robust protection to withstand temperature fluctuations, moisture exposure, rough handling and general shipping wear and tear.

Eco-Friendly Benefits of Molded Fiber Packaging

Molded fiber packaging offers significant environmental advantages over traditional materials, making it a smart choice for brands committed to sustainability.

Recycled Content

Molded fiber packaging is primarily made from post-consumer recycled paper and natural fibers. By repurposing materials that would otherwise end up in landfills, eco-friendly packaging helps reduce overall waste and supports a circular economy. Using packaging with high recycled content is a tangible way to minimize environmental impact and conserve natural resources.

Fully Recyclable and Compostable

After use, molded fiber packaging can be recycled alongside other paper products or composted in industrial or home composting systems. Unlike many plastic or foam alternatives, molded fiber breaks down naturally and leaves no harmful residues behind. This means various brands can offer packaging that protects their products while also returning safely to the environment at the end of its life cycle.

Reduces Plastic Use

Switching to molded fiber packaging allows brands to significantly reduce their use of plastics, foams and Styrofoam. These traditional materials are increasingly restricted by regulations and less favored by eco-conscious consumers. Molded fiber provides a high-performance, sustainable alternative that meets or exceeds the protective qualities of plastic while aligning with evolving industry standards and customer expectations.

Supports Brand Sustainability Goals

Adopting molded fiber packaging demonstrates a brand’s commitment to environmental stewardship. For example, eco-friendly packaging for wine bottles resonates with 46% of wine consumers who believe packaging is one of the biggest parts of environmental impact. By choosing molded fiber, various producers and retailers can strengthen their brand reputation, meet retailer and regulatory requirements and appeal to a growing market of environmentally aware buyers.

Why Partner With Great Northern Fiber Interior Packaging?

Choosing the right packaging partner is as important as choosing the right material. Fiber Interior Packaging offers expertise, customization and industry-leading testing to ensure your products are protected and your brand stands out.

We offer:

- Custom solutions: Get tailored designs, ensuring a perfect fit for your products.

- In-house ISTA® 6 testing: We’re certified to conduct ISTA® 6 testing to verify that your packaging meets strict shipping standards. This lessens the risk of damage and returns, protecting your products throughout the supply chain.

- Amazon Packaging Support and Supplier Network (APASS) membership: We’re recognized by Amazon for frustration-free packaging, ideal for online sales.

- Sustainability leadership: Fiber Interior Packaging helps brands achieve their environmental goals with fully recyclable and compostable solutions.

Ready to Protect Your Products Sustainably?

Make the switch to eco-friendly, custom protective packaging that elevates your brand and safeguards your products. Contact us today for a custom quote tailored to your packaging needs.

Experience the benefits of molded fiber for your brand and the planet.