The shipping process supports industries and economies around the world, equipping communities and businesses with vital goods and technology that make life fuller and better.

However, travel over land and sea exposes these goods to great risks if they are not protected properly. Bumps, sudden turns and accidents can damage and destroy fragile items, which can be especially harmful for businesses in manufacturing, e-commerce and logistics. In the first quarter of 2025 alone, USPS lost $848 million to controllable losses like these.

Molded fiber packaging helps solve this problem by providing customized protective packaging, which can support and insulate fragile goods from the forces they are exposed to in transit. It can save businesses money spent on repairs and replacements, protect their reputations and satisfy customers by delivering goods intact.

This article examines molded fiber packaging applications and how they can protect fragile items during shipping.

The Challenge of Shipping Fragile Items

Fragile items like glassware, wooden goods and fluid containers are vulnerable during the many stages of the shipping process. From loading and unloading to transport across ocean lanes and highways, these goods can be jostled, scraped, cracked and broken entirely. This damage often results in extensive replacement costs for businesses.

The most common causes for this damage are:

- Shoddy or careless packaging

- Poor handling

- Treacherous travel conditions, like potholes, sharp turns, harsh waves and turbulence

Numerous tools are used to combat these difficult conditions and protect fragile items on their journey. Some of the most common are:

- Packing paper

- Packing peanuts

- Bubble Wrap

- Polystyrene foam supports

- Moving blankets

- Tie-down straps

- Zip ties

- Custom wooden boxes and corrugated boards

These mechanisms are not perfect, however. While they may be enough under most conditions, they must be used carefully and precisely to maximize protection and minimize harm. Many of these options are also expensive and less than sustainable, increasing costs and environmental damage simultaneously. Polystyrene foam alone contributes heavily to plastic pollution, spreading microplastics into the environment and the bodies of the animals and people that live there.

What Is Molded Fiber Packaging?

Molded fiber packaging is one of the most sustainable and innovative shipping protection solutions out there. It leverages recycled pulp — such as paperboard and newsprint — to form a protective barrier between the goods being shipped and the container carrying them.

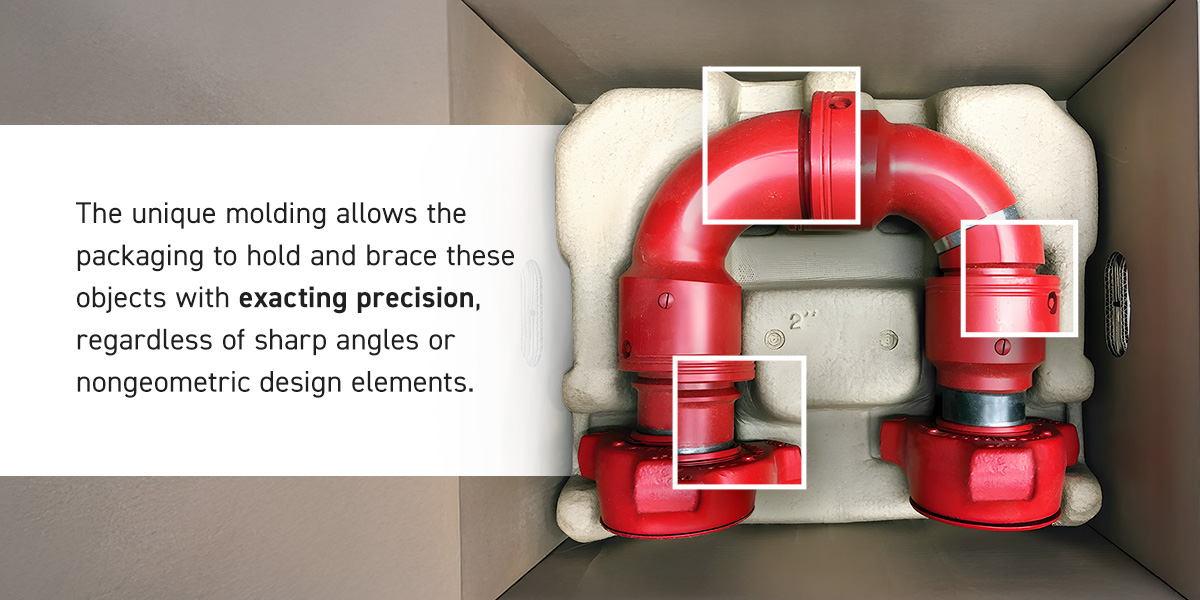

This packaging is molded with specific items in mind, such as glass jars, appliances, sporting goods, paint cans and everything in between. The unique molding allows the packaging to hold and brace these objects with exacting precision, regardless of sharp angles or nongeometric design elements.

Molded fiber packaging comes in four main types:

- Thick-walled: This oven-baked variant of molded fiber packaging is designed to handle larger, heavier items like chairs and tires. The walls it is named for sit between 3/16 and 3/8 inches thick, several times the thickness of thinner variants like thermoformed packaging. Another distinguishing feature of these molds is their texture. Typically, one side of the packaging is smooth while the other is rough.

- Transfer-molded: This packaging is made using two molds — a forming mold and a transfer mold — and is then oven-dried. This process typically results in a smooth barrier that ranges in thickness from 1/8 to 3/16 inches. You’ve likely seen this type of packaging in egg cartons, but it’s also used to protect glass and electronic equipment during shipping.

- Thermoformed: The thinnest type of molded fiber packaging, thermoformed packaging is also made using forming and transfer molds. It is not oven-dried, however, resulting in a smooth surface with a wall thickness of 3/32 to 5/32 inches.

- Processed: This variant is created by treating the packaging in unique ways after it is molded and cured. This treatment can add print, colors or new features entirely. Processed packaging is the most customizable of the four types.

The Power of Molded Fiber Packaging

Molded fiber packaging provides custom-built support and protection for various goods, which is vital when your business handles fragile objects or items with unconventional proportions. The molded shape of the packaging prevents rolling and shifting inside the container, creating a perfect niche for the object to rest within at both the top and bottom. The mold absorbs impacts and prevents scrapes.

The molded fiber packaging is designed to fit perfectly within corrugated boxes and other containers. Protecting glass items during shipping is far easier with these double layers of protection. Healthy cooking oils, for instance, are kept safe and secure within the packaging.

This durability and flexibility are especially important for oddly shaped objects. Computer parts and vehicle components, for example, face unique challenges in transit thanks to their shape and sensitivity. Molded fiber packaging can accommodate these unconventional shapes and keep them stable and safe, even within containers subjected to jostling and sliding.

The Sustainability of Molded Fiber Packaging

In a world increasingly concerned with pollution and climate change, sustainability is a vital part of business operations of all sizes. Shipping is just as important in many cases, and unfortunately, it can be quite taxing on the environment. Maritime transport alone accounts for 3% of global emissions. The many containers and packaging protections that enable this shipping also contribute to the problem.

Molded fiber packaging is a direct response to this problem. Made of recycled pulp from a variety of sources, this packaging can protect items in transit and then reenter the recycling process through curbside recycling. It’s even biodegradable, meaning it can feed back into the environment without disrupting it, should it end up outside the local recycling center. This sustainability can significantly reduce your business’s environmental impact as a whole.

Protect Your Fragile Items With Fiber Interior Packaging

Shipping doesn’t have to be costly or unsustainable. At Fiber Interior Packaging, we prioritize your needs and those of the environment. Our molded fiber packaging can be shaped to your exact specifications, protecting everything, from healthy cooking oils to sump pumps, from breakage. It’s easy to store, use and recycle. We design our molded fiber packaging with its entire lifespan in mind, and that starts with considering your business’s needs.

To learn more about our approach to sustainability and our custom-built packaging, fill out our contact form or give us a call at 920-212-4132.