Sustainable Packaging for the Manufacturing Industry

You produce dependable equipment parts and components, and your packaging should be just as reliable. It makes a statement about your brand, assuring everyone who chooses your parts that you care about quality. Today’s market encourages you to protect your products and be kind to the planet with your material choices. Your industrial packaging can be durable, sustainable and protective when you choose Great Northern Fiber Interior Packaging.

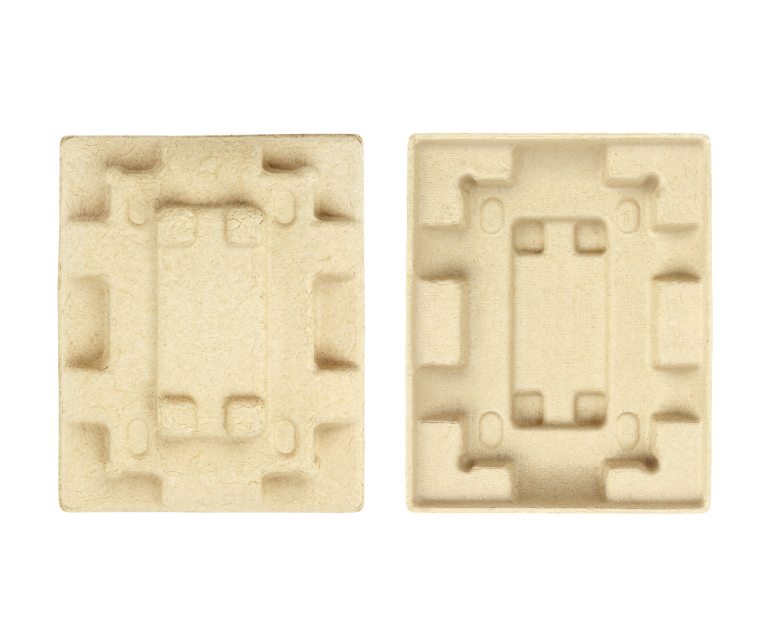

We create molded pulp fiber from used corrugated cardboard and newsprint. These custom-fit interior packaging solutions protect contents from common dangers, like drops, compression, vibration and impact.

Why Manufacturers Are Switching to Sustainable Industrial Packaging Options

Using packaging materials like airbags and foam creates a massive amount of waste that resists breaking down and harms the environment. Research finds that 72% of all plastic packaging used is not recovered for a second use cycle. However, that plastic isn’t truly lost. As much as 40% of it ends up in a landfill, while the other 32% ends up elsewhere — dumped into the environment or otherwise left behind. Consumers identify more strongly with companies that dedicate themselves to sustainable practices, products and packaging.

That’s where Fiber Interior Packaging comes in. Our molded pulp fiber inserts are 100% recyclable and biodegradable, meaning they benefit the environment whether or not they enter another use cycle. Sustainable packaging from Fiber Interior Packaging has other benefits, too. It’s better for your brand, easier to open and often more versatile than traditional packaging materials. In addition, eco-friendly packaging reduces your carbon footprint, avoids toxins common in plastic materials, optimizes storage utilization and makes recycling simple for distributors or end users.

Key Benefits of Fiber Interior Protective Packaging for Manufacturing

Beyond their sustainability, molded pulp fiber manufacturing packaging solutions have several advantages compared to their alternatives:

- Custom-fit for excellent protection: Designed specifically for your products, protective molded inserts fit each item and box perfectly. They hold your parts securely, preventing damage during storage and transport.

- Reduced time and labor requirements: Some interior packaging solutions require extra time to fold and pack. These easy-to-use packaging options allow your team to focus more time on production and other high-value tasks.

- Shipping efficiency: These lightweight inserts cut shipping costs because you pay only for what your products weigh.

How Manufacturers in All Industries Are Seeing Results

Whether you want to improve your company’s brand image through your commitment to sustainable packaging or need to select more labor-friendly and effective packaging, our solutions can help. Explore our case studies to see how Fiber Interior Packaging became a key part of several companies’ success stories.

Upon request, we can test your packaging in our certified International Safe Transit Association (ISTA®) test lab to ensure it meets our standards. Our solutions can also accommodate Amazon’s Frustration-Free Packaging Program standards.

Upgrade to Sustainable Packaging Today

Get greater protection for your products and the planet with custom-fit, sustainable manufacturing packaging solutions from Fiber Interior Packaging. Ready to make the switch and improve how your parts get where they’re going? Complete our contact form to learn more from one of our specialists. We look forward to designing consistent molded pulp inserts that secure your machinery and components.

Let’s Get Started

Tell us a few details about your product, so we can provide a solution that works for you!